What Happens in the Winding House of a Mine?

What Happens in the Winding House of a Mine? This is for Technology Grade 8 mini PAT project.

Welcome to your mini-PAT project! Over the next four weeks, you’ll be working in teams to design and construct a mine-lifting system. This system, also known as mine shaft headgear, is crucial for transporting miners and ore between the surface and the underground. Your project will involve both designing and building a model that includes a mine winch, shaft headgear, and lift cage.

What Happens in the Winding House of a Mine

The winding house, also known as the hoist house, is a key component of the mine-lifting system. It houses the machinery and controls needed to operate the lift that moves miners and materials in and out of the mine. Here’s what happens in the winding house:

- Control of the Lift System:

- The winding house contains the control systems that manage the movement of the lift cage. Operators use these controls to ensure safe and efficient transportation of miners and ore.

- Operation of the Mine Winch:

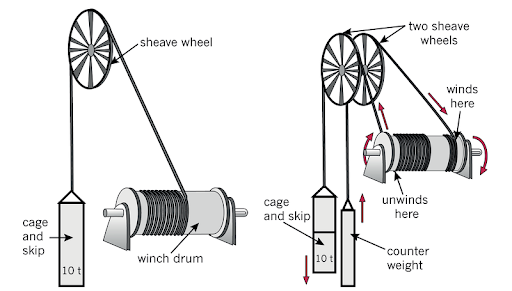

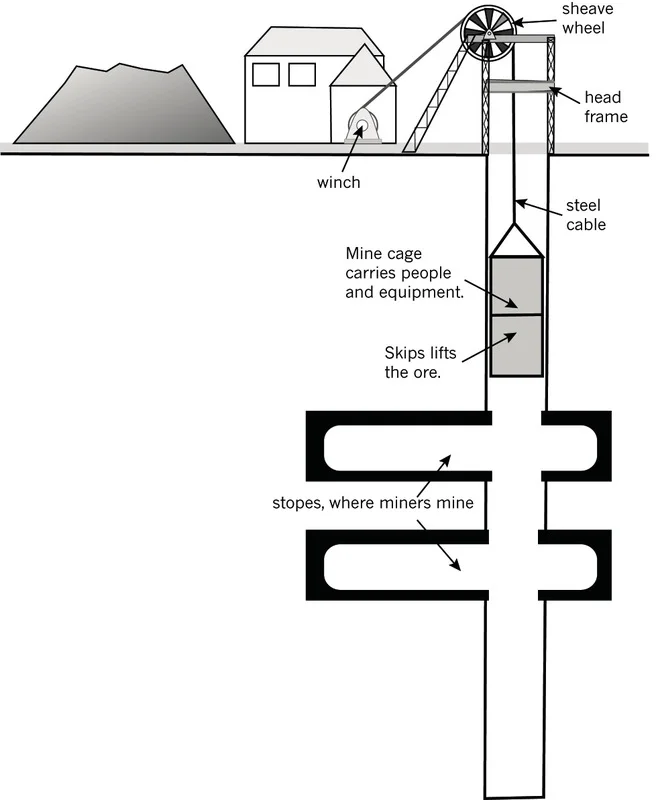

- The mine winch, located in the winding house, is a powerful motor-driven drum that winds and unwinds the steel cable connected to the lift cage. This winch is responsible for raising and lowering the lift cage through the mine shaft.

- Safety Mechanisms:

- Various safety mechanisms are in place within the winding house to prevent accidents. These include emergency brakes, speed regulators, and communication systems to ensure constant contact between the surface and underground workers.

Components of the Mine-Lifting System

To understand the winding house better, let’s look at the main components of the mine-lifting system you will be designing and modeling:

- Mine Winch:

- This is the heart of the lifting system, responsible for moving the lift cage up and down the mine shaft. It must be powerful enough to handle the weight of the lift cage, miners, and ore.

- Shaft Headgear:

- The headgear is the structure at the top of the mine shaft. It supports the pulleys and cables used by the winch to move the lift cage. It must be sturdy and tall enough to ensure smooth operation of the lifting system.

- Lift Cage:

- The lift cage is the elevator that carries miners and ore. It needs to be spacious, strong, and safe, with adequate ventilation and lighting.

Steps to Complete Your Mini-PAT Project

- Form Teams:

- Organize yourselves into teams, each acting as a mechanical engineering company.

- Research and Design:

- Investigate existing mine-lifting systems. Look at different designs and technologies used in mine winches, headgear, and lift cages.

- Plan Your System:

- Sketch detailed designs of your proposed lifting system. Ensure your design includes all necessary components and safety features.

- Construct the Model:

- Build a scale model of your lifting system. Use materials that best represent the real components. Your model should include a functioning winch, headgear, and lift cage.

- Prepare Your Tender:

- Write a detailed proposal explaining your design and how it meets the requirements of a mine-lifting system. Highlight the safety features and efficiency of your design.

- Present Your Model:

- Present your model and tender to the class. Explain how your system works, its safety features, and why it is the best solution for the mine.

Conclusion

By understanding what happens in the winding house and how each component of the mine-lifting system works together, you’ll be well-equipped to design and build an effective model. Good luck with your mini-PAT project, and remember, safety and efficiency are key!